Products

- Mask Machine (2)

- Bottle Labeling Machine (13)

- Automatic Labeling Machine (13)

- Custom-made Labeling Machine (13)

- Semi-automatic Labeling Machine (6)

- Card/Bag/Pouches Labeling Machine (1)

- Box/Carton Labeling Machine (4)

- Automatic Side Labeling Machine (2)

- Double Sided Labeling Machine (3)

- Production Line Labeling Machine (4)

- Print and Apply Labeling Machine (2)

- Filling machine (3)

- Screw Machine Series (7)

- Ultrasonic series (2)

Automatic Labeling Machine

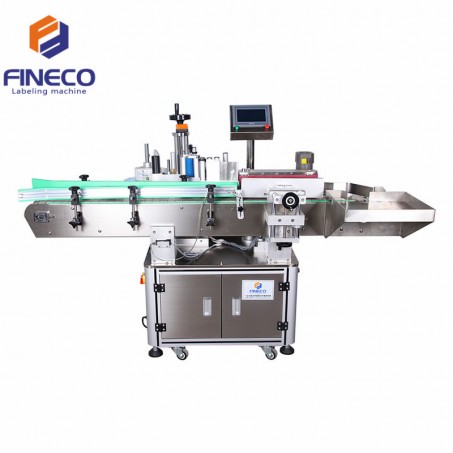

FK803 Automatic Round Bottle Labeling Machine

Application:

*For all kinds of cylindrical,tapered objects wrap around labeling.

*Widely used in food, cosmetic, chemical, pharmaceutical and other industries.It can work alone or connect to production line.

*Date printer can be added to print production date,batch lot and expiry date while labeling.

*Support customization.

Customer Case:

Parameters:

Parameter

Data

Label Specification

adhesive sticker, transparent or opaque

Labeling Tolerance

±1mm

Capacity(pcs/min)

30 ~ 80

Suit bottle size(mm)

Ø25~Ø100;Can be customized

Suit label size(mm)

L: 20-290; W(H): 20-130

Machine Size(L*W*H)

≈1935*1200*1530 (mm)

Pack Size(L*W*H)

≈1950*1300*1550 (mm)

Voltage

220V/50(60)HZ;Can be customized

Power

655W

N.W (KG)

≈185

G.W(KG)

≈360

Label Roll

ID: Ø76mm;OD:≤260mm

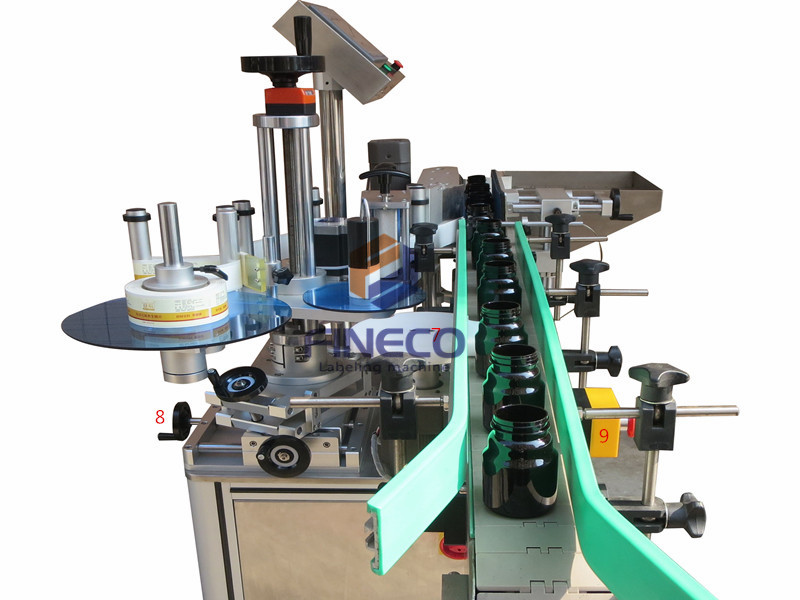

Structures:

|

No. |

Structure |

Function |

|

1 |

Double Side Guardrails |

keep the bottles goes straightly, can be adjusted according to the diameters of the bottles.

|

|

2 |

Labeling Head |

core of the labeler,including label-winding and driving structure. |

|

3 |

Touch Screen |

operation and setting parameters. |

|

4 |

Rotary Belt |

driven by a motor to rotate products while labeling. |

|

5 |

Electric Box |

place electronic configurations. |

|

6 |

Collection Plate |

collect the labeled products. |

|

7 |

Spacing Wheel |

makes every 2 products keep certain distance . |

|

8 |

Adjusters |

used to adjust labeling position. |

|

9 |

Emergency Stop |

stop the machine if it runs wrong. |

Features:

1 ) Control System:Japanese Panasonic control system , with high stability and extremely low failure rate.

2 ) Operation System:Color touch screen , directly visual interface easy operation.Chinese and English available . Easily to adjust all electrical parameters and have counting function , which is helpful for production management.

3) Detection System:Using German LEUZE/Italian Datalogic label sensor and Japanese Panasonic product sensor , which are sensitive to label and product , thus ensure high accuracy and stable labeling performance . Greatly saves labor .

4) Alarm Function : The machine will give an alarm when problem occur , such as label spill , label broken , or other malfunctions .

5) Machine Material : The machine and spare parts all use material stainless steel and anodized senior aluminum alloy , with high corrosion resistance and never rust .

6) Equip with a voltage transformerto adapt to local voltage.

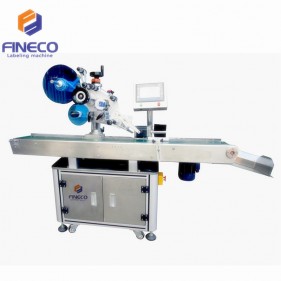

Related Products

FK807 Automatic Horizontal Round Bottle... Customer Case: Parameters: ...

FK816 Automatic Tamper Evident Labeling...

Customer Case:

Parameters:...

FK816 Automatic Tamper Evident Labeling...

Customer Case:

Parameters:...  FK811 Automatic Plane Labeling Machine

Customer Case:

Parameters:

...

FK811 Automatic Plane Labeling Machine

Customer Case:

Parameters:

...