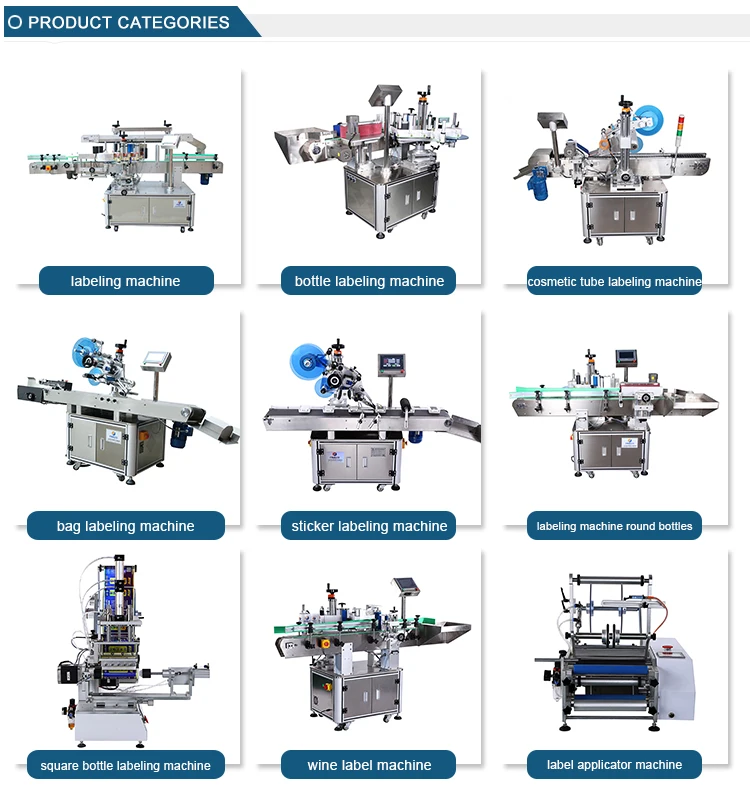

Products

- Mask Machine (2)

- Bottle Labeling Machine (13)

- Automatic Labeling Machine (13)

- Custom-made Labeling Machine (13)

- Semi-automatic Labeling Machine (6)

- Card/Bag/Pouches Labeling Machine (1)

- Box/Carton Labeling Machine (4)

- Automatic Side Labeling Machine (2)

- Double Sided Labeling Machine (3)

- Production Line Labeling Machine (4)

- Print and Apply Labeling Machine (2)

- Filling machine (3)

- Screw Machine Series (7)

- Ultrasonic series (2)

Filling machine

All-in-one machine for filling, capping and labeling(for disinfectant)

Application:

applied range:And material contact material imported 304 l material, no particles can be all kinds of corrosive resistant low viscosity fluid, such as: all kinds of reagents (medicine oil, wine, alcohol, eye drops, syrup), chemicals (solvents, acetone), oil (feed oil, essential oils, cosmetics (toner, makeup water, spray), food (high temperature resistant to 100 degrees, such as milk, soy milk), beverages, fruit juice, fruit wine, spices, soy sauce vinegar, sesame oil, etc without granular liquid;High and low foam liquid (nursing liquid, cleaning agent)

■The whole line adopts advanced human-computer interface, operation parameters can be stored and adjusted, fault can be displayed, and it is easy to use;

■The whole line is made of stainless steel and aluminum alloy, with a beautiful appearance

■The filling machine is safe and easy in operation, and can control the illing amount according to the time, and has a wide compatible range

■The whole line equipment has a reasonable structure layout, which is easy to disassemble and clean, and makes it easier in care and maintenance;

■All the contact materials of the filling machine are made of 316 stainless steel, which is of good acid and alkali resistance and corrosion resistance;

■The cap- screwing machine may be equipped with a vibrating disk, which can cap and uncap automatically, and the cap dropping track, capping head and bottle gripper adopt hand wheel control, which is convenient and simple

■The cap- -screwing machine can adapt to bottles of various specifications within scope of application by adjusting the tightness of gripper belt and the height of capping head without replacing parts.

■The labeling machine adopts the new step drive,the speed of labeling is fast,and the labeling performance is stable.

* Filling of food, medical,cosmetic,chemical and other bottle liquids. Plus:wine,vinegar, soy sauce, oil,

Water,etc.

* Widely used in food, cosmetic, chemical, pharmaceutical and other industries.It can work alone or connect to production line.

*Support customization.

Customer Case:

Six - head magnetic pump automatic filling line

parameter configuration:

1.Metering method: Time and speed adjustment, suitable for almost all liquid products.

2.the size of the container, the container phi 20-30-350 mm 160 mm tall

3. packaging, weight, more than 2 g

4.Packing precision: Packing weight≤100g deviation≤±1g > 100g deviation≤±1% (test is based on water)

5.the packing speed: 25-60 cans/min (according to the nature of the bottle and filling liquid, 6 head filling machine, 300 ml, for example, 2000-2500 bottles per hour)

6.power supply: single-phase 220 v, 50 hz

7.the weight: 150 kg

8. the machine power: 1Kw

9. machine volume: 2000×1000×1400mm

10. magnetic pump flow range 10-5500 ml/min (take water as an example). Each working pump is separately controlled. The test is based on sending sample bottles.

11. Filling volume: 10-2000ml

Fully automatic multi-function cap screwing machine

applied range:This equipment is used in food and beverage, pesticide and fertilizer, chemical industry plastic bottle glass bottle automatic hanging cap screw, straight line hanging cap preturning cap, can be applied to a variety of bottle, bottle change simple and fast, high production efficiency.

performance feature:

1. Full automation, in line with GMP requirements, high yield.

2. The machine can be operated by a single machine or used with the whole line.

3. It can be customized as required.

4. Applicable to a variety of bottle types. When the cap screw reaches the time of cap screw, the cap will stop automatically to protect the cap and bottle from damage.

technical parameters:

1. Model :HM - GJC - 16

2. Suitable cap shape:Plastic, metal round cover, pump head cover, duck mouth cover, etc

3.The sealing height:30-300CM

4.Sealing diameters:16-70CM

5.production speed:20-50 bottles per minute

6.operating voltage:AC220V 60Hz

7. working air pressure:0.4-0.6 MPa

8.length width and height:1920*74*160CM

9.package size:2002*82*176CM

10.weight:140KGS

Automatic electromagnetic induction aluminum foil sealing machine

Features:

composite electromagnetic induction aluminum foil sealing technology is contemporary international recognized advanced seal technology, the non-contact heating to adapt to the characteristics of plastic (PP, PVC, PET, ABS, HDPE, PS, DURACON) glass bottles and various sealing compound plastic hose and so on, is the pharmaceutical, food, oil, cosmetic, household, agrochemical bottled sealing the most advanced technology, walk in the forefront of industry technology level core elements adopt international famous brand, products more strict inspection, so the quality is stable and reliable.

Device model: XSY-2300s

conveyor belt speed: 0-12.5 m/min

Sealing diameter: 15-150 Optional

sealing speed: 0-200 bottles/min

voltage: AC220V50/60Hz

Cooling mode: Air cooling

power: 1300~2800W Optional

packing size: 850X250X1370MM

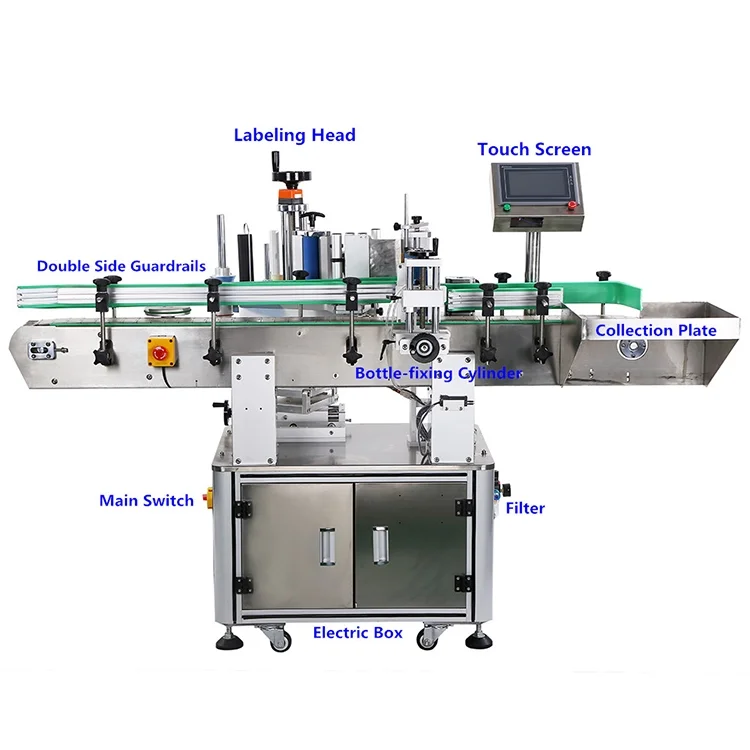

Automatic round bottle labeling machine

Suitable for round bottle labeling, can do single-labeling and double labeling, the labeling position can beadjusted casily. Widely used in cosmetics, food, pharmaceuticals, disinfectant and other industries.

Key technical parameters:

Labeling accuracy: ±1mm (excluding product and label errors);

Speed of labeling (PCS /min) : 25 ~ 60 pieces /min (related to product and label size);

Suitable product size: (for round bottle) and height: diameter: 25mm ~ 140mm Height: 25mm ~ 300mm

Applicable label size: Length: 20mm ~ 380mm ;Width (width of backing paper) : 20mm ~ 130mm;

Machine size: about 1950mm×1200mm×1530mm (length × width × height);

Power supply: 220V 50/60Hz;

Machine weight: about 185Kg.

SPEFICATION

1,Model Name:HM-CLB-06

2,Voltage:AC220V 50hz

3,Power:960W

4,Speed range:200~4000rpm

5,Production capacity:1500~2200/Hour

6,Filling accuracy:≤±1% ;±5g

7,Measurement method:Positive displacement gear pump time quantification

8,Filling direction:From left to right (the operator faces the host)

9,Preset air pressure:1~5(bar)

10,Installation size:100X350X1600mm

Features:

Main configuration:

1,For 6-head filling mainframe:Stainless steel square pass 50X50 thickness 1.5mm welding, stainless steel panel:thickness1.0mm;

2,The length of the conveyor belt is 2 meters, and the height of the conveyor belt from the ground to the panel is 700~800mm adjustable;

3,Using 82.6mm POM plate chain plate;

7,Selection of main components:

Taiwan Weilun 7-inch color touch screen human-machine interface, PLC programmable controller, French Schneider, Japanese Izumi electrical components, South Korea Autonics photoelectric sensor, Taiwan Shannai solenoid valve, Taiwan Shannai cylinder, Taichuang motor, Taiwan Mingwei Power.

Q: Are you the factory?

A: We are Manufacturer located in Dongguan,China.Specialized in labeling machine and packaging industry for more than 10 years,have thousands of customer cases,welcome for factory inspection.

Q:How to make sure your labeling quality is good?

A:We are using strong and durable mechanical frame and premium electronic parts such as Panasonic,Datasensor,SICK...to make sure stable labeling performance.What’s more,our labelers approved CE and ISO 9001 certification and have patent certificates.Besides,Fineco was awarded Chinese“New High-Tech Enterprise” in 2017.

Q:How many machines your factory have?

A:We produce standard and custom-made adhesive labeling machine.By automation grade,there are semi automatic labelers and automatic labeler;By product shape,there are round products labelers,square products labelers,irregular products labelers,and so on.Show us your product, labeling solution will be provided accordingly.

Q:What’s your quality assurance terms?

Fineco strictly implement responsibility of the post,

1)When you confirm order,the design department will send the final design for your confirmation before production.

2)The designer will follow the processing department to ensure each mechanical parts are processed correctly and timely.

3)After all parts done,designer transfer responsibility to the Assembly Dept,which need to assemble the equipment on time.

4)Responsibility transferred to Adjustment Dept with the assembled machine.Sales will check the progress and feedback to customer.

5)After customer’s video checking/factory inspection,sales will arrange the delivery.

6)If customer have problem during application,Sales will ask the After-sales Dept to solve it together.

Q:Confidentiality Principle

A:We will keep All Our Clients’ Design,Logo,and Sample on our archives,and never show to the similar clients.

Q: Is there any installation direction after we received the machine?

A: Generally you can apply the labeler directly once receive it,because we have adjust it well with your sample or similar products.Besides,instruction manual and videos will be provided.

Q: What label material does your machine use ?

A: Self-adhesive sticker.

Q: Which kind of machine can meet my labeling requirement?

A:Pls supply your products and label size (picture of labeled samples is rather helpful), then suitable labeling solution will be suggested accordingly.

Q:Is there any insurance to guarantee that I will get the right machine I pay for?

A:We are an on-site check supplier from Alibaba. Trade Assurance provides quality protection, on-time shipment protection and 100% safe payment protection.

Q:How could I get the spares of machines?

A:Non-artificial damaged spares will be sent freely and shipping free during 1 year’s warranty.

Related Products

25-250ml/30-300ml/50-500ml Liquid...

Semi-automatic weighing single-head filling machine (oil drum)...

25-250ml/30-300ml/50-500ml Liquid...

Semi-automatic weighing single-head filling machine (oil drum)...  automatic Nucleic acid testing tube...

Parameters:

Labeling accuracy: ± 1mm (excluding product...

automatic Nucleic acid testing tube...

Parameters:

Labeling accuracy: ± 1mm (excluding product...